Ukuprintwa kwiphepha le-thermal kuye kwanda kakhulu kwiminyaka yakutshanje ngenxa yokulula ukusetyenziswa kunye nokukwazi ukuvelisa ushicilelo oluphezulu.

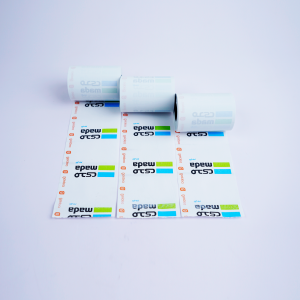

Iphepha le-Thermal luhlobo lwephepha elifakwe kwikhemikhali ekhethekileyo. Inkqubo yokushicilela ibandakanya ukufudumeza i-coating ukudala umfanekiso ocacileyo kunye ochanekileyo kwiphepha. Umthombo wobushushu udla ngokuba ngumshicileli we-thermal, esebenzisa intloko yoshicilelo lwe-thermal ukuvelisa ubushushu obuyimfuneko.

Enye yeenzuzo eziphambili zokushicilela kwiphepha le-thermal yisantya sayo. Ekubeni i-inki okanye iikhatriji ze-toner zingafunwa, inkqubo yoshicilelo ikhawuleza kakhulu kunezinye iindlela zokushicilela. Oku kwenza kube yinto efanelekileyo yokushicilela umthamo ophezulu, njengendawo yokuthengisa apho iirisithi kufuneka ziveliswe ngokukhawuleza.

Ukongeza kwisantya, ushicilelo lwephepha olushushu lukwabonelela ngomgangatho ogqwesileyo wokuprinta. Ubushushu obuveliswa yi-printhead bubangela ukusabela kweekhemikhali kwi-coating, kubangele imifanekiso ecacileyo kunye neenkcukacha. Oku kuluncedo ngakumbi kumbhalo woshicilelo, iibhakhowudi, kunye nemizobo elula. Ezi prints zikwanodaka kwaye zifiphala zixhathisa, ziqinisekisa ukuba umyalezo uhlala ufundeka ekuhambeni kwexesha.

Ukongeza, ukuprintwa kwephepha le-thermal kunoqoqosho. Ekubeni akukho zixhobo ezisetyenziswayo ezifana ne-inki okanye i-toner ebandakanyekayo, iindleko eziqhubekayo kuphela kukuthenga iphepha lomqulu we-thermal. Oku kuyenza ibe sisisombululo esinexabiso eliphezulu kumashishini afuna ukuprinta ngokuqhubekayo, njengoko anokonga imali ebalulekileyo kwi-inki okanye kwitoni.

Ngaphandle kwezi nzuzo, ukuprintwa kwephepha le-thermal kunemida ethile. Okokuqala, ushicilelo lunovelwano kubushushu, ukukhanya kunye nokufuma. Ukuvezwa ixesha elide kwezi zinto kunokukhawulezisa inkqubo yokuphela, kubangele umgangatho woshicilelo ukuthotywa ngokuhamba kwexesha. Ngoko ke, kubalulekile ukugcina ukuprintwa kwamaphepha e-thermal kwindawo epholileyo, eyomileyo.

Okwesibini, ukuprintwa kwephepha le-thermal kunokhetho oluncinci lwemibala. Ngokungafaniyo ne-inkjet okanye abashicileli belaser, abanokuvelisa uluhlu olubanzi lwemibala, abashicileli be-thermal basebenzisa kuphela imibala embalwa esisiseko, njengomnyama nobomvu. Oku kunokuba yingozi kumashishini afuna iiprinta eziqaqambileyo kunye nemibala.

Okokugqibela, ukuprintwa kwephepha le-thermal akunakutshintshwa ngokulula okanye kuhlelwe. Emva kokuba umfanekiso ushicilelwe, usisigxina kwaye awukwazi ukulungiswa. Oku kunokuba yingozi kwiimeko apho ulwazi lokushicilela kufuneka luhlaziywe rhoqo okanye lulungiswe.

Ukushwankathela, iphepha le-thermal linefuthe lokushicilela ngokukhawuleza, umgangatho wokushicilela ophezulu kunye nokusebenza kweendleko eziphezulu. Lukhetho oludumileyo lwamashishini afuna ushicilelo olukhawulezayo noluthembekileyo, olufana nokuthengisa okanye ibhanki. Nangona kunjalo, kubalulekile ukuqwalasela le mida kwaye uthathe amanyathelo afanelekileyo ukuqinisekisa ixesha elide kunye nomgangatho wokuprintwa kwephepha le-thermal. Ngokubanzi, ukuprintwa kwephepha le-thermal sisisombululo esifanelekileyo kunye nesisebenzayo kwiimfuno ezahlukeneyo zokuprinta.

Ixesha lokuposa: Nov-15-2023