Iphepha le-Thermal luhlobo lwephepha olusetyenziswa ngokuqhelekileyo olusetyenziswa kakhulu kumashishini ahlukeneyo nakumacandelo. Ithandwa kakhulu kwiivenkile, iibhanki kunye namashishini ononophelo lwezempilo ngenxa yokukwazi ukuvelisa iiprinta ezikumgangatho ophezulu ngokukhawuleza nangempumelelo. Ukuqonda indlela ukuprintwa kwephepha le-thermal kunokubonelela ngolwazi oluxabisekileyo kwitekhnoloji emva kwayo kunye nokusetyenziswa kwayo.

Itekhnoloji yoshicilelo lwe-Thermal isebenzisa uhlobo olukhethekileyo lwephepha eliqatywe ngekhemikhali ebizwa ngokuba yi-thermal coating. Ukwaleka kuqulathe idayi ezingenambala kunye nezinye iikhemikhali ezingevani nobushushu. Lobu buvakalelo kubushushu obuvumela iphepha ukuba liprinte ngaphandle kwesidingo se-inki okanye itoner.

Inkqubo yokushicilela iphepha le-thermal ibandakanya intloko yokushicilela i-thermal, eyona nxalenye ephambili ejongene nokufudumala i-thermal coating. I-printhead iqulethe izinto ezincinci zokufudumeza (ezikwabizwa ngokuba yi-pixels) ezicwangciswe ngendlela ye-matrix. Ipixel nganye ihambelana nendawo ethile kumfanekiso oprintiweyo.

Xa umsinga wombane udlula kwizinto zokufudumeza, zivelisa ubushushu. Lo bushushu busebenzisa i-thermal coating kwiphepha, ibangela ukusabela okuvelisa ushicilelo olubonakalayo. I-Thermal coating itshintsha umbala ngenxa yobushushu, ukudala imigca, amachaphaza, okanye umbhalo ephepheni.

Enye yeenzuzo eziphambili zokushicilela kwiphepha le-thermal yisantya sayo. Ekubeni akukho inki okanye toner efunekayo, inkqubo yoshicilelo ingagqitywa ngokukhawuleza. Oku kwenza ukuba ushicilelo olushushu lube lulungele izicelo ezifuna umthamo ophezulu kunye noshicilelo olukhawulezayo, olufana neerisithi, amatikiti, kunye neelebhile.

Ukongeza, ushicilelo lwephepha olushushu lubonelela ngomgangatho ogqwesileyo wokuprinta. Iiprinta ze-Thermal zivelisa ushicilelo olucacileyo, oluchanekileyo, kunye nokumelana nokuphelelwa. I-Thermal coating iqinisekisa ukuprintwa kwexesha elide, ilungele amaxwebhu afuna ukujamelana neemeko ezinzima, ezifana nokugcinwa kwiindawo ezishushu okanye ezinomswakama.

Ukuprintwa kwephepha le-Thermal nako kuneendleko ezifanelekileyo. Ngaphandle kwesidingo se-inki okanye iikhatriji ze-toner, amashishini anokonga imali kwizinto ezithengwayo. Ukongeza, abashicileli be-thermal banogcino oluphantsi xa kuthelekiswa nabashicileli bemveli kuba akukho i-inki okanye iikhatriji ze-toner ezinokuthi zibuyisele okanye zicoceke.

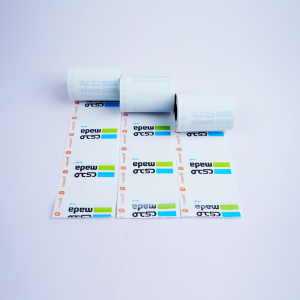

Kukho izicelo ezininzi zokuprinta iphepha le-thermal. Kwishishini lokuthengisa, iphepha le-thermal lihlala lisetyenziselwa iirisithi zokuqinisekisa ukuba ukuthengiswa kweentengiso kubhalwe ngokuchanekileyo. Kwishishini lebhanki, iphepha le-thermal lisetyenziselwa ukuprinta iirisithi ze-ATM kunye neengxelo. Kukhathalelo lwempilo, isetyenziswa kwiithegi, iibhanti zesandla kunye neerekhodi zolwazi lwesigulane.

Nangona kunjalo, kubalulekile ukuqaphela ukuba ushicilelo lwephepha le-thermal lunemida ethile. Kufanelekile kuphela ukuprinta okumnyama nomhlophe, njengoko i-thermal coating ayikwazi ukuvelisa ukuprintwa kombala. Ukongeza, ushicilelo lwe-thermal lunokuphela ngokuhamba kwexesha ukuba luvezwe kwilanga elithe ngqo okanye amaqondo obushushu aphezulu, ngoko ke ugcino olufanelekileyo lubalulekile ekugcineni ubomi babo obude.

Ukushwankathela, ukuprintwa kwephepha le-thermal yitekhnoloji yoshicilelo esebenzayo neyongayo. Ngokusebenzisa i-coating ekhethekileyo ye-thermal kunye nobushushu obuveliswa yintloko yokuprinta, iphepha le-thermal livelisa ushicilelo oluphezulu ngaphandle kwesidingo se-inki okanye i-toner. Isantya, ukuqina, kunye nokucaca kwayo kuyenza ibe lukhetho oludumileyo kumashishini ahlukeneyo. Nangona kunjalo, kubalulekile ukuqwalasela imida yayo, njengokungakwazi ukuvelisa ushicilelo lwemibala kunye nokubakho kokuphela kwexesha. Lilonke, ushicilelo lwephepha olushushu luhlala luyinketho ethembekileyo neguquguqukayo kumashishini nakubantu ngokufanayo.

Ixesha lokuposa: Nov-14-2023